-

-

-

ZSW Vibrating FeederThanks to the transmission part processed with quenching and high temperature tempering technology, the superior quality becomes a possibility.

Our vibrating material feeding equipment is an optimal choice for the users, because of the low noise, less power consumption, and low operation and maintenance cost.

-

-

-

-

CZG Vibrating FeederApart from outstanding shock resistance, the vibrating feeder is distinguished by large carrying capacity and good elasticity.

The low noise generated creates comfortable working environment for the users.

-

-

-

-

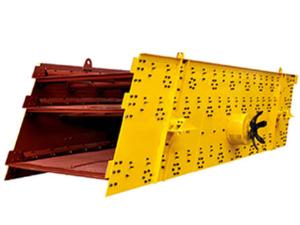

ZSB Linear Vibrating ScreenDesigned with small amplitude, the vibrating screening machinery has optimal grading performance and large screening capacity.

The linear screening equipment generates low noise during operation. In addition, the energy consumption is less, compared with other common product.

-

-

-

-

YK Circular Vibrating ScreenThe sieve plate of the circular vibrating screen is produced from national standard seamless tube connected by high-strength bolt for good stability and durability.

The employment of air cooling technology for the vibrator is conducive to the extended lifespan of the bearings for the material screening machinery.

-

-

-

-

PE Jaw CrusherAdopting multi-pass welding and internal stress eliminating technology, the machine body of the construction machinery has high strength.

To ensure the interior quality of the jaw crusher, we particularly manufacture the product with precision machining and assembling technology.

-

-

-

- PEX Jaw CrusherThis rock crushing machinery is extensively used in certain industries, including mining, metallurgy, building material, transportation, ceramics, chemical industry, electric power, infrastructure construction, etc. It enjoys sound reputation because of the following features.

-

-

-

-

PF Impact CrusherThe crushed materials are in good particle shape. The content of the flaky and elongated particles is reduced by over 8%.

For high strength, the machine body of the crushing equipment is multi-pass welded and processed with internal stress eliminating technology.

-

-

-

- PC Impact CrusherEnergy-saving, the impact crusher is capable of increasing the production capacity by 30%. Apart from that, the flaky and elongated particles, as well as the powder contained in the crushed material, are reduced by 20%.

-

-

-

- WPC Impact CrusherThe material crushing device is warmly welcomed by the industry such as building material, electric power, chemical industry, mineral separation, road and bridge construction, and infrastructure construction.

-

-

-

-

CS Cone CrusherThe hydraulic system is conducive to the easy, convenient and labor-saving operation of the cone crusher.

Adopting combined type crushing chamber, the stone crushing machinery offers high rate of finished product in cubic shape.

-

-

-

-

PYB Cone CrusherIn addition to the outstanding size reduction ratio, the construction machinery is very popular because of the high production capacity and low wear rate.

Thanks to the high-strength cast steel rack, our cone breaker is sturdy and durable for use.

-

-

-

-

PX Fine CrusherUnique adjusting mechanism for the fine crushing equipment enables high use ratio of the hammerhead and the sieve plate.

Requiring less maintenance, the high-strength fine crusher is capable of saving 20% operating cost for the users.

-

-

-

- 2PG Roll CrusherThanks to the convenient adjustment of the spring, the roll crusher has low failure rate and high safety. The granularity of the discharged material can be adjusted within the range of 2-10mm, resulting in optimal fine crushing capacity.

-

-

-

- Mobile Crushing PlantBased on actual production demand, the circular vibrating screen of the wheel mounted crushing plant can be dismantled for direct primary crushing of the raw material.

-

SHANTUI JANEOO MACHINERY CO., LTD.

Fax: +86-531-89815268

English

English Français

Français Русский

Русский Español

Español Português

Português